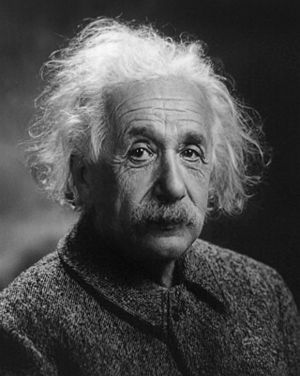

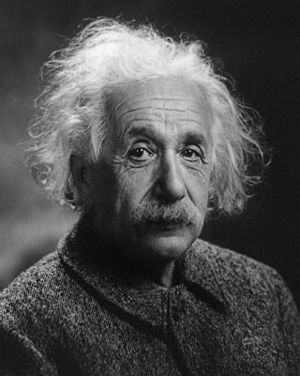

When Einstein first introduced his theory of concentrated light in the 1920s, what would later be known worldwide as laser light, it’s possible that he had some idea of the capabilities that his theory would offer to mankind. (He was a genius after all.) For the rest of humanity, it took until the 1960s to actually figure out a way to put his theory into practice and, at that time, the modern laser cutter was born.

Since then there has been tremendous advancements in laser technology and with them laser cutting technology. When you compare the materials that can be cut, the precision that can be achieved and the power to cut even thick pieces of metal that today’s laser cutting machines offer to what was available even a scant 10 years ago you’ll quickly see that laser cutting technology is improving by leaps and bounds.

Today for example there are laser cutting machines to be found in high school shop classes and, with a bit of practice, students can create an infinite amount of objects out of an almost infinite amount of materials. The most common of course is cardboard because it’s cheap but suffice to say that these machines are quite capable of cutting incredibly precise, detailed and delicate designs from many other materials. There are larger firms like Garcross laser cutting, who’ve invested heavily in laser technology.

If you are a radio control airplane enthusiast or see yourself as a designer of action figures (and you have a few extra thousand bucks to spare because let’s face it as much as prices have dropped these machines still aren’t free), intricate airplane parts as well as fully articulated action figures can be made with some of the laser cutting models that are on the market today. The same goes for someone who’d like to create instruments, chess pieces, and practically anything the imagination can come up with.

Look in many automobile shops these days and you’ll find laser cutters there helping mechanics to fix cars, motorcycles and other vehicles. The ability to create replacement or custom parts with a laser cutter gives these men and women the opportunity to get things done much quicker and cheaper than ever before. Indeed, if you watch any of the myriad of reality shows on TV about motorcycle, car or even fish tank customizers you’ll see a laser cutter in their shop almost every time.

Maybe you’re an interior designer and you’d like to create a unique lampshade or other home décor item for a client. With a laser cutter you can not only cut your item in cardboard first to see how it looks but once it’s ready you can grab your acrylics, metals and other materials and cut them also.

Simply put, the advancements in laser cutting technology have been fantastic. Today the sky’s the limit when it comes to possibilities for laser cutters and, believe us, new products and ideas are popping up every day. If you have access to a modern laser cutter you should consider yourself lucky. You have one of the most advanced cutting tools that’s ever been made by man and with it a world of possibilities for creating practically anything your mind can dream up.